The company produces precision parts to contract on the basis of drawings supplied by clients through the creation of a dedicated production process, the construction of tools necessary for the carrying out of processes, the creation of products from raw materials in bar form or moulded with the use of structural steel, through mechanical machining carried out either in-house or through qualified suppliers, as well as thermal and surface treatments carried out by specialised collaborators.

Our services

Our services

Raw materials

We use bar-form or hot-moulded raw materials, and create structural steels, in particular hardening steel, case-hardening steel, induction tempering steel and nitriding steel.

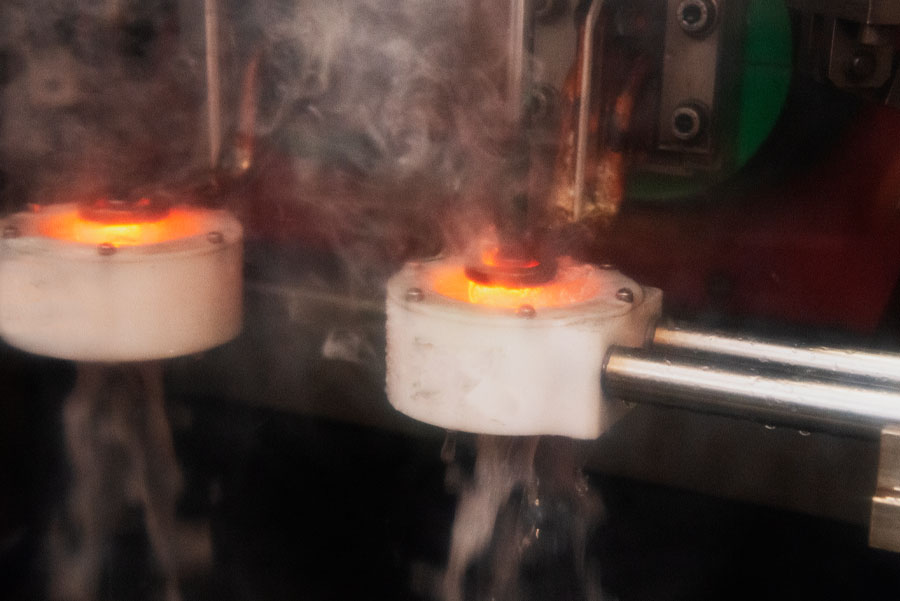

Heat treatments

In-house application of induction tempering treatments, and out-sourced hardening, nitriding, carbon-nitriding and case-hardening.

Components for assembly

Procurement from specialised suppliers of laser sliced or cut parts to be assembled and/or welded onto components machined in-house.

Surface treatments

The treatments most commonly used in our production processes include galvanisation, phosphating, nickel, chrome and molybdenum plating, Molykote coating and painting.

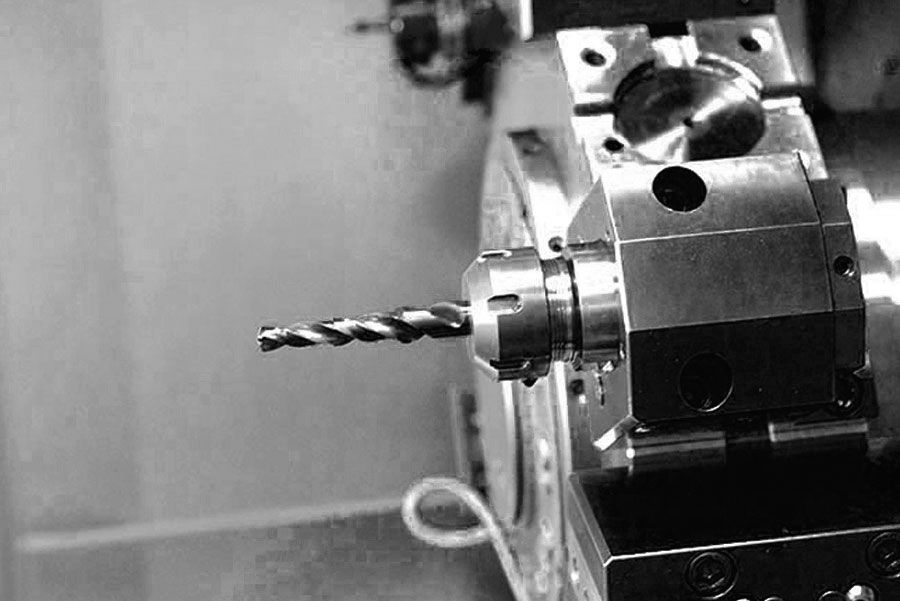

Machining

In-house machining processes include cutting, drilling, turning, milling and centreless grinding. Additionally, the turning of small parts, toothing, deep drilling, centred grinding and welding is outsourced.

Abroad

Our company supplies more than 35% of its products to over 20 foreign countries, including Germany, England, Belgium, France, Austria, Spain, Poland, Hungary, Turkey, Croatia, the United States, Canada, Mexico, Argentina, Brazil, India and China.