Grazioli Angelo & F.lli was founded in the 1950s, a period that, more than any other time in Italian history, was characterised by important productive, economic and social progress.

Mission

The management of Grazioli Angelo & F.lli aims to consolidate the company’s presence in the European and non-European markets in which it operates.

Certification

Thanks to “Quality Management Certification”, since 2000 the company has been certified as compliant with regulatory requirements.

The Company

Grazioli Angelo & F.lli was founded in the 1950s, a period that, more than any other time in Italian history, was characterised by important productive, economic and social progress.

Mission

The management of Grazioli Angelo & F.lli aims to consolidate the company’s presence in the European and non-European markets in which it operates.

Certification

Thanks to “Quality Management Certification”, since 2000 the company has been certified as compliant with regulatory requirements.

0

Covered area (mq)0

Employees0

Total area (Mq)

Our services

Our products

-

Rail shafts

-

Planetary Pinions

-

Shafts

-

Small welded components

-

Forged items and Spacers

-

Forks

These are made from C45/42CrMo4 (tempering steel) using the induction tempering treatment. Production ranges in diameter from Ø 10 to Ø 35 and in length from 40 mm to 800 mm.

These are made from 16 Mncr5/18NiCrMo5 (case-hardening steel) with the case-hardening tempering or nitriding process. Production ranges in diameter from Ø 14 to Ø 80 and in length from 40 mm to 400 mm.

Shafts are made with tempering, hardening or case-hardening steels. In the case of drive shafts, the gear toothing is carried out by a specialised supplier. Components are subjected to case-hardening tempering or induction tempering. Production ranges in diameter from Ø 20 to Ø 100 and in length from 100 mm to 700 mm.

Our small welded components are made in C40 hardening steel and sheered with structural steel. Production ranges in diameter from Ø 10 to Ø 35 and in length from 80 mm to 500 mm.

Forged items and spacers are made from structural, tempering or hardening steel. Production ranges in diameter from Ø 20 to Ø 150 and in length from 40 mm to 400 mm.

Made from induction-tempered structural steel.

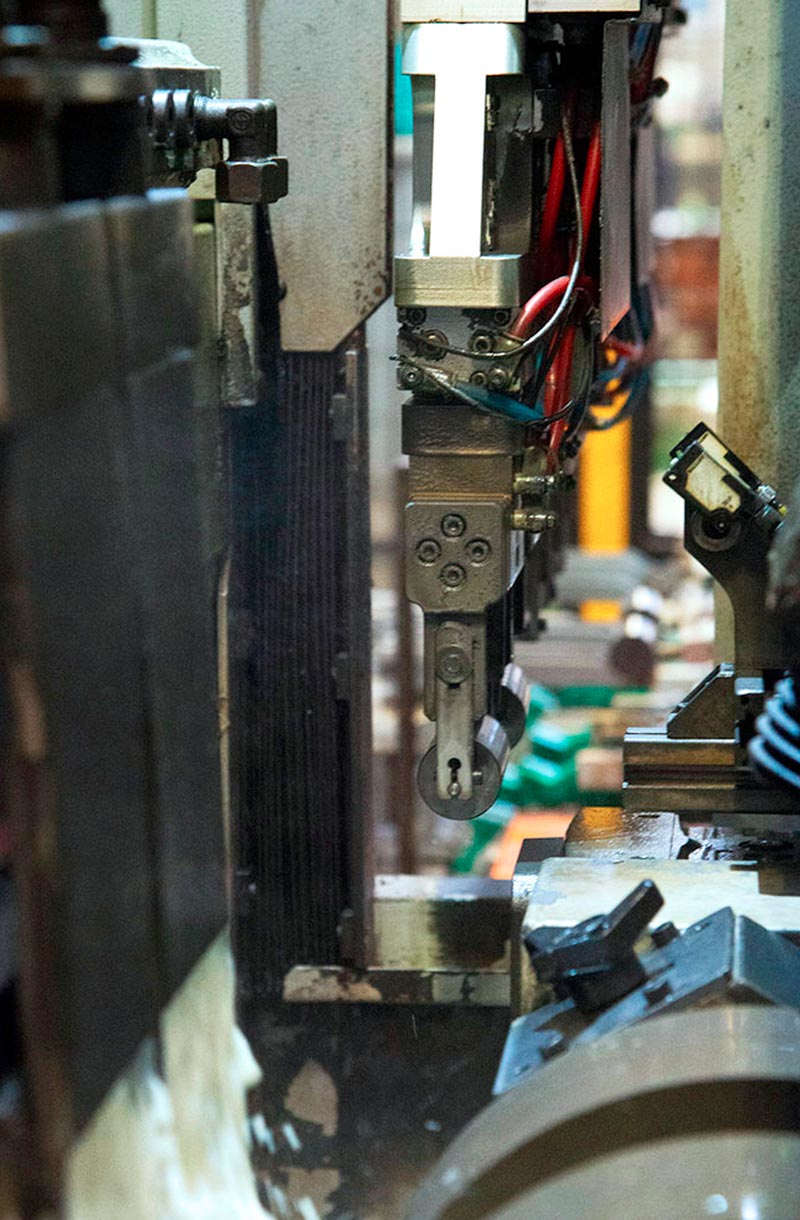

Our production departments

Cutting – no.7 systems

Il The cutting of materials in bars is carried out with the use of cutting machines, transfer cutting machines and turning machines with diameters ranging from Ø 6 to Ø 80 and lengths from 30 mm to 2000 mm.

Turning – no.13 CNC lathes

The company has a bar turning department composed of both sliding- and fixed-head lathes for machining shafts of a diameter of between Ø 10 and Ø 60 and a length of between 50 mm and 1000 mm, as well as a secondary turning department for the machining of forged items or sections up to a diameter of Ø 150 and a length of 300 mm.

Milling – no.14 machining centres

Milling and drilling of components is carried out on vertical machining centres, transfer machines and numerical control grinding machines.

Induction tempering – no.6 systems

High- and medium-frequency induction tempering is carried out in-house with the use of systems ranging from 35 to 100 kw on items with a diameter of between Ø 8 and Ø 80 and with a maximum length of 1 m.

Grinding – no. 10 centerless grinders

Generally, our parts are finished via the process of outside diameter grinding with the use of manual and/or automatic-loading centreless grinders.

Tooling

The tooling department allows for the in-house creation of tools to support general production, as well as the creation of prototypes and small runs and pre-runs of new components.

Warehouse, logistics and shipping

This department includes the raw-materials, semi-finished and finished product warehouse, and the washing, assembly, protection, packing and shipping of products.

Quality control

The quality control department includes a laboratory certified for the carrying out of dimensional, surface and metal controls on the products created.